What’s the difference between insulated glass and vacuum glass? Let me give you a comprehensive science lesson!

Release date:

2025-09-01

Double-glazed glass was invented by Americans in 1865. It is a modern building material that offers excellent thermal and sound insulation, enhances aesthetic appeal, and helps reduce the overall weight of structures. This innovative material is crafted by bonding two (or three) panes of glass together using high-strength, highly air-tight composite sealants, along with an aluminum alloy frame containing desiccants inside. The result is a highly efficient type of glass that provides superior soundproofing and thermal insulation. The primary components include glass, aluminum spacers, corner seals, butyl胶, polysulfide胶, and desiccants.

Let’s start by going into detail about vacuum glass:

What is vacuum glass?

Vacuum glass is created by sealing two flat panes of glass around the edges, leaving a gap in between. This gap is then evacuated to create a vacuum and sealed off at the vent hole. The inner surfaces of the two glass panes are coated with one or two layers of transparent, low-emissivity film. Essentially, vacuum glass achieves a "vacuum" between the two layers—meaning there’s virtually no gas left inside; it’s truly empty.

In 1993, the world's first 1-meter-by-1-meter vacuum glass sample was unveiled—created by Tang Jianzheng, a physicist from Peking University, and R.E. Collins.

Vacuum glass refers to a structure where two layers of glass are sealed with a vacuum in between—though the vacuum layer itself is quite thin. To maintain pressure equilibrium between the inside and outside of the glass, flexible or rigid support elements are carefully arranged between the panes, ensuring they can withstand the force exerted by external atmospheric pressure. Vacuum glass is typically a custom-made product, and due to the significant atmospheric pressure involved, it demands particularly high manufacturing standards. In principle, vacuum glass can be compared to a flat, insulated thermos flask.

The difference between vacuum glass and a thermos bottle is:

1. Vacuum glass used for doors and windows must be transparent or translucent; it cannot have an opaque silver coating like a thermos flask. Instead, it is coated with various types of transparent, low-emissivity films.

2. Vacuum glass is created by transforming a cylindrical or spherical thermos—designed to evenly withstand pressure—into a flat panel. To achieve this, a grid of "support structures" must be strategically placed between the two layers of glass, enabling the pane to endure approximately 10 tons of atmospheric pressure per square meter. These supports keep the glass layers separated, maintaining the vacuum layer essential for its exceptional insulation properties.

The spacing of the "support" array is designed based on the glass panel’s thickness and mechanical properties, ranging between 20 mm and 40 mm. To minimize heat transfer caused by the "thermal bridge" formed by the supports—and to make them nearly invisible to the human eye—the supports themselves are extremely small, with diameters ranging from 0.3 mm to 0.5 mm and heights between 0.1 mm and 0.2 mm.

3. In addition to its excellent thermal insulation properties, vacuum glass offers an even greater advantage: superior soundproofing. Thanks to the vacuum layer, which prevents noise from traveling through, vacuum glass can block up to 90 percent of external noise.

Product advantages:

1. Low-carbon and energy-efficient

2. Heat insulation and thermal preservation

3. Soundproofing and noise reduction

4. Prevents condensation

5. Widely applicable

Next, let's talk about hollow glass:

What is insulated glass?

Contrary to its name "hollow glass," it's not actually empty—there’s a "gas" trapped between the two layers of glass. In most cases, this gas is ordinary air, though higher-quality versions often use argon instead. Since the gas is invisible to the naked eye, it’s simply referred to as "hollow."

Double-glazed glass was invented by Americans in 1865. It is a modern building material that offers excellent thermal and sound insulation, enhances aesthetic appeal, and helps reduce the overall weight of structures. This innovative material is crafted by bonding two (or three) panes of glass together using high-strength, highly air-tight composite sealants, along with an aluminum alloy frame containing desiccants inside. The result is a highly efficient type of glass that provides superior soundproofing and thermal insulation. The primary components include glass, aluminum spacers, corner seals, butyl胶, polysulfide胶, and desiccants.

Double-glazed glass outperforms ordinary double-pane glass in several key areas, earning it recognition worldwide.

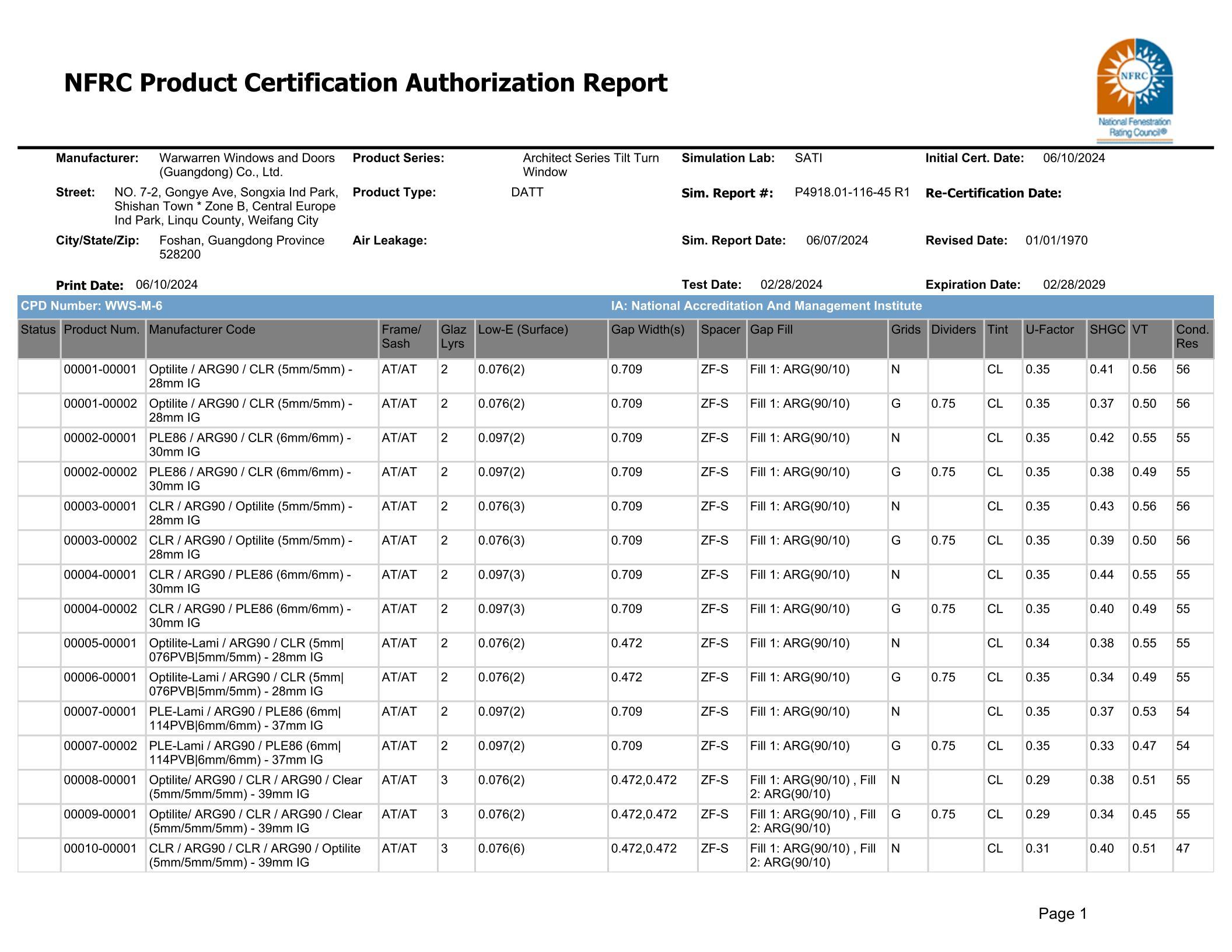

Commonly used hollow glass can be made with original glass sheets measuring 3, 4, 5, 6, 8, 10, or 12 mm in thickness, while the air cavity thicknesses can range from 6, 9, 12, 15, 18, to 21 mm.

High-performance hollow glass differs from ordinary hollow glass in that, in addition to sealing dry air between the two layers of glass, it also features a specially coated, high-performance metal film on the air layer side of the outer glass pane. This coating effectively blocks a significant amount of solar energy from entering the room, enhancing its insulation properties even further. Moreover, the space between the glass layers must be filled with inert gases—argon and krypton—to maximize thermal efficiency.

Similarities and differences between the two:

The similarities between vacuum glass and hollow glass are:

1. Both layers of the laminated glass feature a vacuum with gas pressure below 10⁻¹ Pa, effectively minimizing heat transfer through gas conduction.

2. The inner walls are all coated with a low-emissivity film to minimize radiative heat transfer.

The differences between vacuum glass and insulated glass are:

1. Vacuum glass is significantly thinner than insulated glass, saving both installation space and window frame materials. At the same time, thanks to its excellent thermal insulation properties, it also offers superior anti-condensation and anti-fog performance, eliminating the annoying issues of condensation obscuring the view or water dripping onto the windowsill.

2. Vacuum glass boasts about twice the wind-pressure resistance of conventional hollow glass made from the same type of material, though its impact resistance is slightly lower. This limitation, however, can be effectively addressed by combining vacuum glass with other materials. For instance, at locations where enhanced durability is required, laminated glass technology can be employed—adding tempered glass to one or both sides of the vacuum glass—to create a high-performance safety vacuum glass that excels in both impact and wind-pressure resistance. Of course, this approach will naturally lead to a corresponding increase in cost.

In home renovations, hollow and vacuum glass can be used on balconies, doors, and windows to provide superior insulation, soundproofing, and heat retention.

Latest News

Contact Information

Contact Address: No. 7, Industrial Avenue East, Songxia Industrial Park, Shishan Town, Nanhai District, Foshan City

Warren Doors and Windows, south of Fangshan Road and west of Dongtai Road, Dongcheng Subdistrict, Linqu County, Weifang City, Shandong Province

Become A Deaters :Info@wolunmc.com

National customer service hotline:+86 400-676-9888

WhatsApp:+86-18866798677

Beijing customer service phone number:+86 010-68319888

Douyin

Xiaohongshu

E-mail:

Tel:

400:

The Little Red Book:

Tiktok:

WeChat:

在线客服添加返回顶部

页面顺滑的滚动

右侧在线客服样式 1,2,3 4

图片alt标题设置: Beijing Warren Doors and Windows Co., Ltd.

循环体没有内容时: Materials are currently being organized—stay tuned!

CSS / JS 文件放置地