Do you know how long the lifespan of window and door glass is?

Release date:

2025-09-01

Insulated glass is a composite product made from glass panes, a spacer frame (aluminum strips), desiccants (molecular sieves), and sealing materials (such as butyl胶, polysulfide胶, or structural adhesive). Among these components, the glass and aluminum frame are typically highly stable, meaning the lifespan of the insulated glass depends primarily on the durability of the molecular sieves and sealing materials.

In the natural environment, there is no issue of "aging."

Glass has a chemically stable composition, meaning it doesn’t degrade in performance under natural conditions—whether exposed to sunlight, rain, or fog. Even common acids and bases won’t harm glass, as anyone who recalls their chemistry lab equipment from school can easily confirm.

Typically, there are only two factors that affect the lifespan of glass: humid air and high temperatures. Prolonged exposure to moist air can lead to mold growth on glass, though at normal room temperatures, this process occurs very slowly—often taking several months. In typical usage environments, it’s rare for humid air to persist for such extended periods. As a result, glass left exposed to the air under normal conditions generally won’t develop mold.

Mold typically appears when glass is stored in overlapping stacks, or if it’s kept in damp warehouses—or worse, exposed outdoors and subjected to rain. Interestingly, untreated (non-tempered) raw glass sheets tend to be more susceptible to mold than tempered glass, which has undergone a special heat treatment to enhance its strength and durability.

Ignoring the factor of thermal cracking, temperatures below 300°C have no impact on glass lifespan or chemical stability. However, above 300°C, as the temperature rises, the physical and chemical properties of glass begin to change. Physically, most types of glass start to soften around 600°C. Chemically, higher temperatures can trigger crystallization within the glass structure, causing it to gradually transition from transparent to opaque. At 700°C, this crystallization process—leading to the loss of transparency—typically takes just a few days. In contrast, at 300°C, the same transformation could take months or even years. Meanwhile, at room temperature, the crystallization process that turns glass opaque might occur over tens of thousands of years, making it practically negligible under normal conditions.

The lifespan of tempered glass

Physical tempering involves heating glass and then rapidly cooling it, which alters the structural arrangement of molecules within the glass. Chemical tempering, on the other hand, uses ion exchange to modify the molecular structure of the glass surface at high temperatures. Both methods permanently reshape the glass material's microstructure. As a result, unless exposed to extreme heat or strong chemical reactions, the tempered properties of the glass will remain stable over time under normal usage conditions—showing no signs of degradation or change.

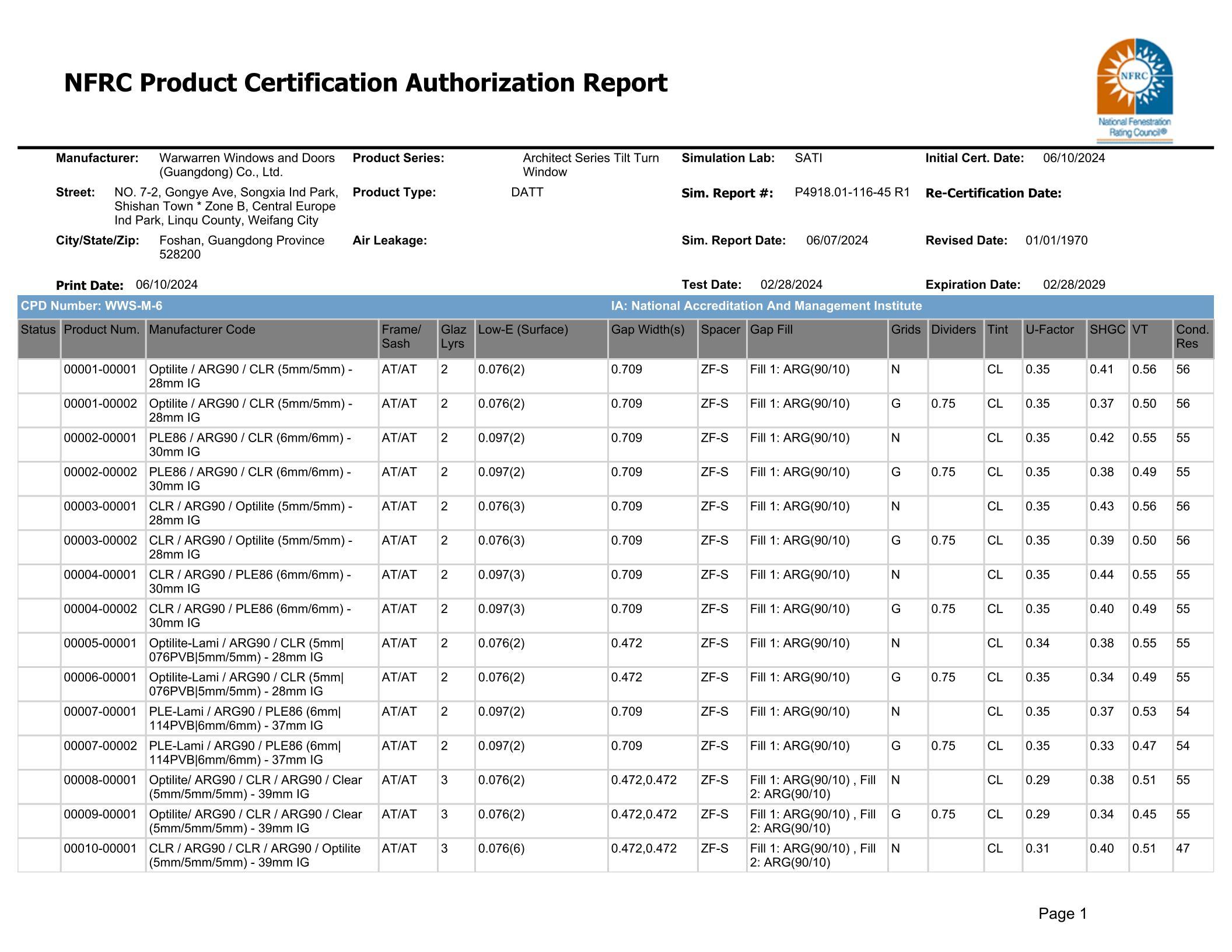

The lifespan of insulated glass

Insulated glass is a composite product made up of glass panes, a spacer frame (aluminum strips), desiccants (molecular sieves), and sealing materials (such as butyl胶, polysulfide胶, or structural adhesive). Among these components, the glass and aluminum frame are typically highly stable, meaning the lifespan of the insulated glass depends primarily on the durability of the molecular sieves and sealing materials.

In a hollow glass system, glass itself is highly stable—as we discussed earlier, the glass substrates typically don’t require consideration for aging under normal conditions. Additionally, the aluminum spacers recommended in standard hollow glass units are all surface-anodized. These anodized aluminum spacers exhibit exceptionally stable physical and chemical properties under typical usage scenarios. Even lower-quality aluminum spacers that lack surface anodization may experience oxidation over time, causing them to lose their luster. However, this does not significantly affect the spacers’ overall performance or functionality.

When it comes to insulated glass units, we need to understand that the true value of the hollow system lies in its ability to provide effective thermal and sound insulation—thanks to the presence of a sealed, dry air cavity. However, as ambient temperatures fluctuate, the gas inside the hollow cavity is constantly subjected to expansion or compression, putting continuous stress on the unit’s sealing system. Meanwhile, external factors like ultraviolet radiation, moisture, and humidity further accelerate the aging process of the sealant, ultimately leading to faster moisture infiltration into the cavity. Once significant amounts of moisture accumulate within the glass unit, the insulating performance is compromised, marking the end of the unit’s functional lifespan. To prevent premature failure, the key lies in using high-quality desiccants and durable sealing materials.

Regarding the lifespan of insulated glass units, Chinese glass manufacturers initially adopted the U.S. standard and introduced the concept of a 10-year warranty period. Later, in the national standard GB/T 11944-2012 for insulated glass, a reference guideline on the material's expected longevity was first established, stating that "the anticipated lifespan of insulated glass should exceed 15 years." In reality, the durability of insulated glass is closely tied to the materials selected, as well as the manufacturing processes involved. Additionally, factors such as the unit's design, structural composition, and the surrounding environmental conditions all play significant roles, making it challenging to quantify its lifespan precisely. For insulated glass units already installed in buildings, a straightforward method to assess their condition is to measure the dew point or the humidity level within the spacer layer.

The lifespan of LOW-E glass

The lifespan of LOW-E glass primarily depends on the longevity of the hollow, sealed system in which it’s installed. We know that the main materials comprising the LOW-E coating are metals, alloys, metal oxides, and metal nitrides. Among these, metal nitrides are typically used as protective layers within the coating structure, offering exceptionally stable performance. Meanwhile, metal oxide and alloy layers usually serve as dielectric layers, connecting the silver layer to the protective coating—and these too exhibit relatively stable properties. The silver layer in LOW-E glass, while somewhat reactive, only oxidizes under specific conditions, namely in the presence of moisture.

Therefore, as long as the insulated glass unit remains functional, there’s generally no need to separately consider the lifespan of the LOW-E coating.

The lifespan of laminated glass

Laminated glass is a composite glass product made by sandwiching one or more layers of organic polymer interlayer film between two panes of glass, then undergoing a specialized manufacturing process that permanently bonds the glass and interlayer together. Even if the glass breaks, the fragments remain securely adhered to the film, effectively preventing injuries from sharp shards and reducing the risk of penetration or falling debris, thus ensuring maximum safety for people.

The lifespan of laminated glass primarily depends on the material used in the interlayer. Typically, wet-laminated glass and EVA laminated glass are mainly suited for indoor partitions and are not recommended for architectural doors, windows, or curtain walls. When exposed to sunlight, both wet-laminated glass and EVA laminated glass accelerate aging—leading to yellowing within 1–2 years. After 2–3 years, issues such as delamination, bubbling, "ice flower" patterns, and fogging may gradually appear. In general, wet-laminated glass tends to degrade much faster than EVA laminated glass. However, if EVA laminated glass is installed indoors away from direct sunlight, it can maintain its integrity for over 10 years.

PVB and SGP laminated glass, commonly used in doors, windows, or curtain walls, exhibit significantly better aging resistance. The most typical failure mode for PVB and SGP laminated glass is delamination—when the glass layers separate from the interlayer, compromising the safety benefits of laminated glass altogether. Currently, there are no specific national standards or guidelines in China regarding the lifespan of PVB and SGP laminated glass. As a result, domestic glass manufacturers typically follow the product warranty periods of 5 to 7 years provided by international PVB and SGP suppliers as their reference.

In fact, the lifespan of PVB and SGP laminated glass is significantly influenced not only by the material of the interlayer but also by the thickness of the intermediate layer, the quality of the laminated glass substrates, and the precision of the lamination process itself.

Latest News

Contact Information

Contact Address: No. 7, Industrial Avenue East, Songxia Industrial Park, Shishan Town, Nanhai District, Foshan City

Warren Doors and Windows, south of Fangshan Road and west of Dongtai Road, Dongcheng Subdistrict, Linqu County, Weifang City, Shandong Province

Become A Deaters :Info@wolunmc.com

National customer service hotline:+86 400-676-9888

WhatsApp:+86-18866798677

Beijing customer service phone number:+86 010-68319888

Douyin

Xiaohongshu

E-mail:

Tel:

400:

The Little Red Book:

Tiktok:

WeChat:

在线客服添加返回顶部

页面顺滑的滚动

右侧在线客服样式 1,2,3 4

图片alt标题设置: Beijing Warren Doors and Windows Co., Ltd.

循环体没有内容时: Materials are currently being organized—stay tuned!

CSS / JS 文件放置地